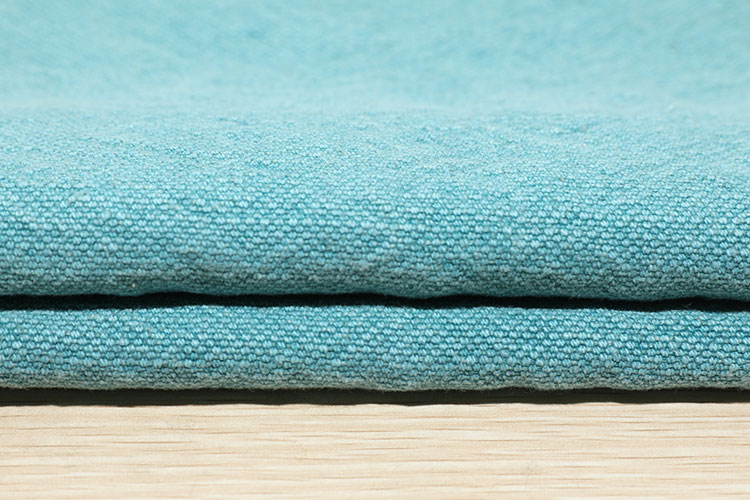

Linen yarn fabric has good health care function. Flax is a plant of the Cryptoceae family, which can emit a faint fragrance. Experts believe that flax has good heat dissipation properties because flax is a bundle of fibers in the fiber. Bundle fibers are formed by the adhesion of flax single cells with the help of colloid. Because there is no more air left, the air permeability of flax fabrics is as high as 25 or more, so its thermal conductivity (breathability) is good. And can quickly and reduce the skin surface temperature 4-8 ℃. The flax fiber is straight and smooth. In the magnified projection of more than 50 times, it looks like a section of bamboo, without distortion of cotton and wool fibers.

Human beings are exposed to ultraviolet rays for a long time, which will damage the body. The hemicellulose contained in linen textile products is the best substance to absorb ultraviolet rays. Hemicellulose is actually immature cellulose. The hemicellulose contained in flax fiber is more than 18, which is several times higher than that of cotton fiber. When it becomes clothing, it can protect the skin from UV rays. Linen fabric can reduce the sweating of the human body than other fabrics, and the water absorption speed of linen textiles is several times faster than that of silk, rayon, and even cotton.

Flax, also known as crow's hemp and flax, can be divided into three categories: fiber, oil, and fiber and oil, all of which are annual herb plants. The flax fiber exists in the bast tissue of the hemp stem. It is soaked and degummed to remove part of the gum, so that the bonded fiber bundles are partially loosened, and then processed into "beaten hemp" by rolling and beating, which is 10 to 20 single Craft fibers composed of fibers. Because of its good hygroscopicity, quick moisture conduction and relatively small diameter, it is one of the main fiber materials for summer clothes.

Usually, the cloth woven from flax fiber is called flax fabric. After the fibers are harvested with flax, they are bundled into small bundles for degumming. The temperature of warm water retting water should be controlled between 28-32°C. After about 100 hours, take it out, put the hemp stalks into an umbrella shape, and dry them in the open. Rain dew retting is made by laying the harvested hemp stems on the grassland or flax field, soaking in rain and dew, and using mold to ferment and retting.

Under suitable humidity conditions, after 7 to 10 days, the retting dry stems are crushed, the xylem and impurities are removed, the fibers are combed, and then classified according to quality. The short hemp that is knocked off is called two hemp.

English

English Chinese

Chinese

+86-573-81880066

+86-573-81880066 +86-13666752302

+86-13666752302 enbo_dong@126.com

enbo_dong@126.com